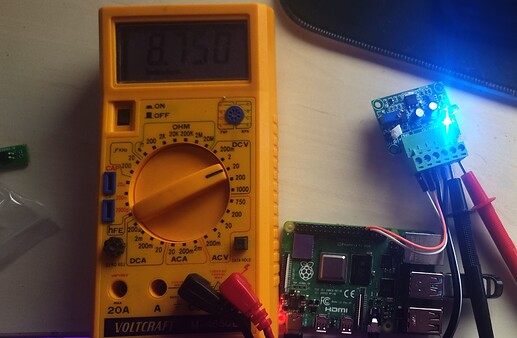

No, that doesn’t explain it… there are many factors that come into play here, the big one is that your little 1 amp power supply (PSU) that you are powering the PWM board with is WAY under-rated to drive LED grow lights. I’m surprised you didn’t burn it out just testing it. Look at your Meanwell drivers… what is the Output rating for the Amps? If you don’t understand the relationship between Amps, Volts, and Watts, I highly recommend you do some more reading or watch some youtube vids that explain basic DC electrical theory as well as Ohm’s Law (V=IR). In fact, I really recommend that you don’t go any further until you have a better understanding of electricity in general.

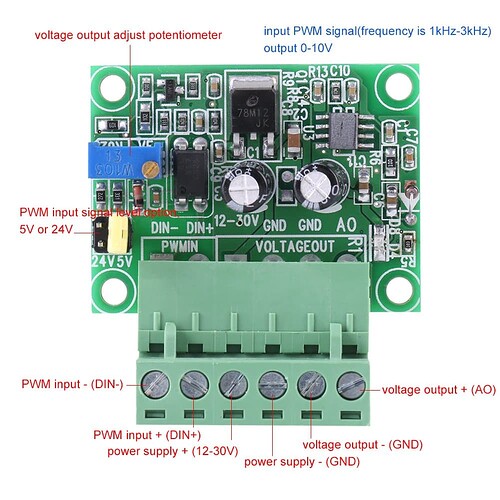

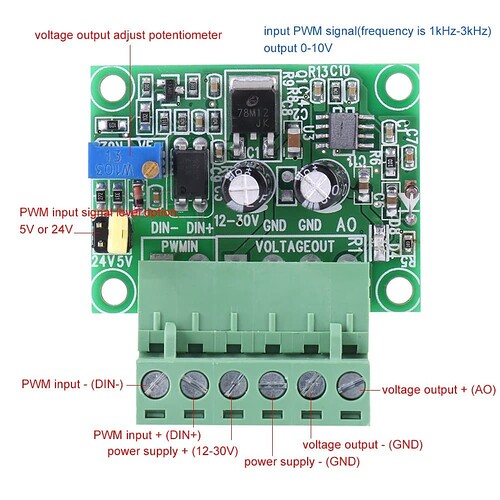

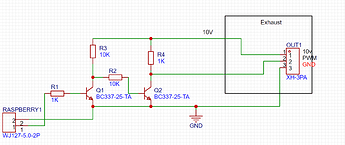

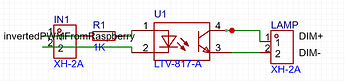

Seriously, I would not use those cheap Amazon PWM boards on your LED lights or with your Meanwell power supplies. Meanwell (and many other LED power supplies) already use built-in “constant voltage PWM” to drive the lights as bright as they can go, without burning them out, while also reducing their waste-heat output. If you alter that PWM frequency or add another PWM signal on top of the PWM signal those drivers are already using, you could burn out your Meanwell drivers or your LEDs. If you power your 10v LEDs with a non-PWM straight 10V DC current, you will likely burn out your LEDs or drastically shorten their lifespan, because they will run too hot, while also looking too dim. PWM isn’t just used to dim LEDs it is also used to over-drive LEDs to make them brighter than they would be by just using straight non-modulated current.

Personally, I don’t think there is any reason to dim LED lights. If your plants are showing signs of light burn, simply raise the lights a few inches away from the plants, or use fewer lights until the plants are mature enough to handle full light. If you feel like you need to dim your lights, I would buy a Meanwell power supply that is dimable, and make sure it is compatible with your lights (correct Voltage and Amperage). In fact, you may want to closely inspect the Meanwell drivers you already have, they might already have their own input for an external PWM signal so you can dim them.

No, it is not the best solution. In fact, I would actually just throw those 10v PWM boards in the trash. They are useless… look at their power rating… only 12 milliamps! That’s barely enough to power a single small computer fan, and it’s the wrong voltage! And the PSU you are running them from is only 1 amp, which means it might be able to handle a 0.5 amp constant load without overheating and burning out. 10v is just not a very common voltage for devices to run on. If you are absolutely sure your duct fan is a 10v DC motor (which I highly doubt) then you would need a MUCH larger PSU.

Absolutely not, there is no “standard voltage” that you can run everything on, so get that idea out of your head. Every device will need it’s own voltage and draw it’s own amperage, therefore every device needs it’s own properly matched power supply. If you try to power a device with a lower voltage, or not enough amperage, you will either damage the device, or burn out the power supply, or even start a fire. Also, trying to run all of your devices from one big power supply might seem like a more efficient way to go, but in reality, you are better off with a PSU for each device… if your one big PSU dies, your whole system is down… if you have several devices all with their own PSUs, at least part of your system will still function until you can replace the bad PSU.

Not sure where you are looking at Meanwell drivers, but most of their drivers I’ve seen come in 12, 24, 36, 48, and 52 volt versions but I don’t see any 10v ones? You may want to post a picture of your meanwell driver’s spec label.

The most common DC voltages are usually multiples of 1.5, 1.2, or sometimes 2.1 volts… because those are the voltages most commonly found in single-cell batteries. Also, most DC devices do not use PWM, they use straight, non-modulated, DC current.